Forklift warning lights and symbols are crucial safety features designed to alert operators of potential issues or hazards. Understanding these indicators is essential for maintaining a safe work environment and preventing accidents. Forklift operators must be familiar with various warning lights, their meanings, and appropriate actions to take when they illuminate. This comprehensive guide will explore common forklift warning lights, their significance, and how to respond effectively to ensure optimal safety and performance.

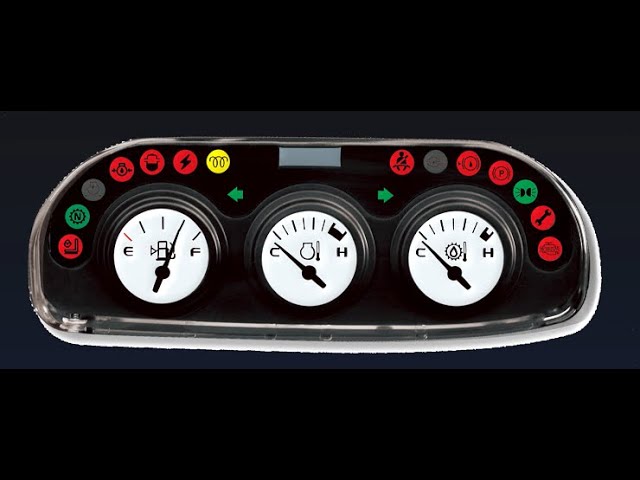

Forklift warning lights typically appear on the dashboard or control panel, using a combination of colors and symbols to convey different levels of urgency. The most common colors used are red, amber, and green, each indicating a different severity level. Red usually signifies critical issues requiring immediate attention, while amber suggests caution or the need for maintenance. Green lights generally indicate normal operating conditions or activated features.

| Light Color | Meaning |

|---|---|

| Red | Critical issue, immediate action required |

| Amber/Orange | Caution, potential problem or maintenance needed |

| Green | Normal operation or feature activated |

Common Forklift Warning Lights and Their Meanings

Understanding the various warning lights and symbols on a forklift is crucial for maintaining safety and efficiency in the workplace. Here are some of the most common forklift warning lights and their meanings:

Engine Oil Pressure Warning Light

This warning light typically appears as an oil can symbol or the letters "OIL" illuminated in red. When this light comes on, it indicates low engine oil pressure, which can lead to severe engine damage if not addressed promptly. Operators should immediately turn off the forklift and check the oil level. If the oil level is adequate, there may be a problem with the oil pump or other engine components, requiring professional inspection.

Battery Warning Light

The battery warning light usually resembles a battery symbol or the word "BATT" lit in red or amber. This light indicates issues with the forklift's electrical system, such as a low battery charge, alternator problems, or loose connections. When this light appears, operators should check the battery connections and charge level. If the problem persists, it may be necessary to replace the battery or have the charging system inspected by a qualified technician.

Temperature Warning Light

Represented by a thermometer symbol or the word "TEMP" in red, this warning light signals that the engine is overheating. Overheating can cause severe engine damage if not addressed quickly. When this light illuminates, operators should safely park the forklift, turn off the engine, and allow it to cool down. Check the coolant level and look for any visible leaks. If the problem continues, professional inspection is necessary to identify and resolve the underlying issue.

Brake System Warning Light

The brake system warning light often appears as an exclamation point within a circle or the word "BRAKE" in red. This light indicates a problem with the forklift's braking system, such as low brake fluid, worn brake pads, or a malfunction in the anti-lock braking system (ABS). When this light comes on, operators should immediately check the brake fluid level and inspect the brake components for visible wear or damage. If the issue persists, professional maintenance is required to ensure safe operation.

Transmission Warning Light

Typically depicted as a gear symbol or the letters "TRANS" in amber or red, this warning light suggests problems with the forklift's transmission system. Issues may include low transmission fluid, overheating, or mechanical failures. When this light appears, operators should check the transmission fluid level and look for any signs of leaks. If the problem continues, professional inspection and repair are necessary to prevent further damage to the transmission.

Responding to Forklift Warning Lights

When a forklift warning light illuminates, it's crucial to take appropriate action to ensure safety and prevent potential damage to the equipment. Here are some general steps to follow when responding to forklift warning lights:

-

Stop operations safely: When a warning light appears, the operator should safely bring the forklift to a stop in an appropriate location, away from traffic and obstacles.

-

Identify the warning light: Consult the forklift's operator manual to determine the specific meaning of the illuminated warning light or symbol.

-

Assess the situation: Evaluate the severity of the issue based on the warning light's color and symbol. Red lights typically require immediate action, while amber lights may allow for continued operation with caution.

-

Perform basic checks: If safe to do so, conduct basic inspections related to the warning light, such as checking fluid levels or looking for visible damage.

-

Report the issue: Inform a supervisor or maintenance personnel about the warning light and any observations made during the initial assessment.

-

Follow company procedures: Adhere to established company protocols for handling forklift warning lights and equipment issues.

-

Do not ignore warning lights: Never disregard or override warning lights, as this can lead to serious accidents or equipment damage.

Maintenance and Prevention

Regular maintenance is key to preventing many issues that trigger forklift warning lights. Implementing a comprehensive maintenance program can help reduce downtime, extend equipment life, and improve overall safety. Consider the following preventive measures:

-

Conduct daily inspections: Perform thorough pre-shift checks of all forklift systems, including fluid levels, tire condition, and safety features.

-

Follow manufacturer guidelines: Adhere to the manufacturer's recommended maintenance schedule for oil changes, filter replacements, and other routine services.

-

Train operators properly: Ensure all forklift operators are well-trained in recognizing and responding to warning lights and other equipment issues.

-

Keep detailed records: Maintain accurate logs of all maintenance activities, repairs, and warning light occurrences to identify patterns and potential recurring issues.

-

Address minor issues promptly: Don't wait for small problems to escalate into major repairs. Address minor issues as soon as they are detected.

Advanced Warning Systems and Technology

Modern forklifts often incorporate advanced warning systems and technology to enhance safety and efficiency. These systems may include:

-

Digital displays: Many newer forklifts feature digital dashboards that provide detailed information about the equipment's status and any potential issues.

-

Telematics systems: These systems can remotely monitor forklift performance, track maintenance needs, and alert managers to potential problems before they become critical.

-

Proximity warning systems: Advanced sensors can detect nearby objects or pedestrians, alerting the operator to potential collision risks.

-

Load weight indicators: These systems warn operators when a load exceeds the forklift's safe lifting capacity, helping to prevent tip-overs and other accidents.

-

Automated maintenance reminders: Some forklifts can automatically notify operators or maintenance personnel when routine services are due.

By leveraging these advanced technologies, businesses can improve forklift safety, reduce downtime, and optimize their equipment management processes.

FAQs About Forklift Warning Lights, Symbols and Meanings [Detailed]

- What should I do if multiple warning lights come on simultaneously?

Stop the forklift immediately, turn off the engine, and report the issue to your supervisor or maintenance team for a thorough inspection. - Can I continue operating a forklift if an amber warning light is on?

While amber lights indicate caution, it's best to have the issue checked before continuing operation to ensure safety and prevent potential damage. - How often should forklift warning lights be tested?

Warning lights should be checked daily as part of the pre-shift inspection process to ensure they are functioning correctly. - What if a warning light comes on but then goes off?

Even if a light goes off, report the occurrence to maintenance as it may indicate an intermittent issue that requires attention. - Are forklift warning light meanings universal across all brands?

While many symbols are similar, always consult your specific forklift's operator manual for exact meanings and recommended actions.